1. Definition:

Punching holes: use punching equipment and tooling fixtures to punch holes on the required position of the spring steel flat bar. There are generally two kinds methods: cold punching and hot punching.

Drilling holes: use drilling machines and tooling fixtures to drill holes on the required position of the spring steel flat bar, as shown in Figure 2 below.

2. Application:

All spring leaves.

3.1. Before the punching and drilling, check the process inspection qualification mark on the flat bar, and check the specification and size of the flat bar. Only when they meet the process requirements, punching and drilling can be allowed.

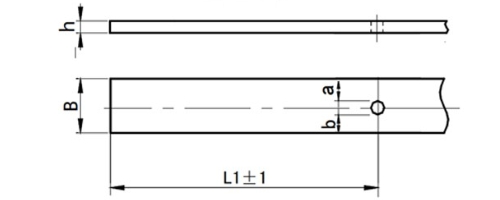

As shown in Figure 1 below, punch the center circular hole. Adjust the locating pin according to L1, B, a and b dimensions.

(Figure 1. Positioning schematic diagram of punching a center circular hole)

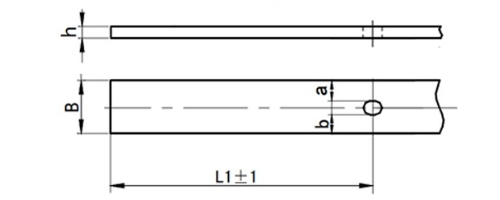

As shown in Figure 2 below, punch the center strip hole. Adjust the locating pin according to L1, B, a and b dimensions.

(Figure 2.Positioning schematic diagram of punching a center strip hole)

3.3. Selection of cold punching, hot punching and drilling

3.3.1. Applications of cold punching:

1) When the thickness of spring steel flat bar h<14mm and the diameter of central circular hole is greater than the thickness h of spring steel flat bar, cold punching is suitable.

2) When the thickness of spring steel flat bar h≤9mm and the center hole is a strip hole, cold punching is suitable.

3.3.2. Applications of hot punching and drilling:

Hot punching or drilling can be used for spring steel flat bar that is not suitable for cold punching. During hot punching, the medium frequency furnace is used for heating to ensure that the steel temperature is 500-550℃, and the steel flat bar is dark red.

3.4. Punching detection

When punching and drilling a hole, first piece of spring steel flat bar must be inspected firstly. Only it pass the first inspection, the mass production can be carried on. During the operation, special attention should be paid to prevent the positioning die from loosening and shifting, otherwise the sizes of the punching position will exceed the tolerance range, resulting in unqualified products in batches.

The punched(drilled) spring steel flat bars shall be stacked neatly. It is forbidden to place them at will, resulting in surface bruises. The inspection qualification mark shall be made and the work transfer card shall be pasted.

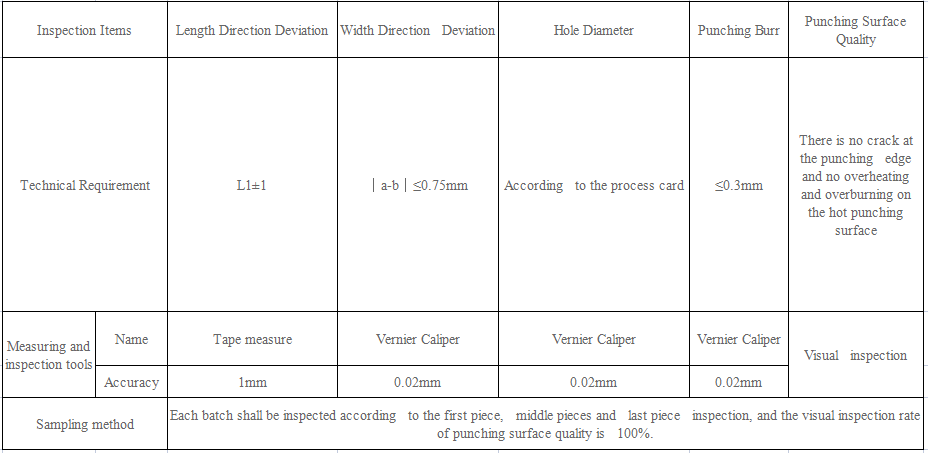

Measure spring holes according to figure 1 and Figure 2. The hole punching and drilling inspection standards are as shown in table 1 below.

Post time: Mar-21-2024