Welcome To CARHOME

9 Tons Axle Air Suspension Leaf Spring

Detail

This item is suitable for Air Suspension Heavy Duty Truck

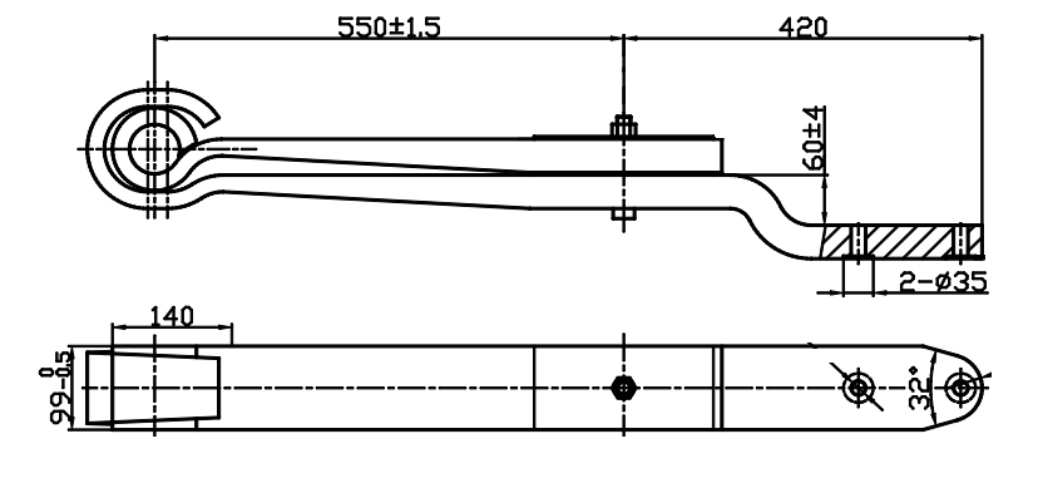

1. The oem number is 2913 300 T01, the specification is 100*40, the raw material is 51CrV4

2. The item total has two pcs, first pcs with eye, use rubber bush the length from the centrl of the eye to the centrl hole is 550mm. The second pcs is Z type, the length from the cover to the end is 970mm

3. The height of the spring is 150mm

4. The painting use electrophoretic painting, the color is drak grey

5. It use with air kit together is the air suspension

6. We also can produce base on client's drawings design

Features of CARHOME Z type air linker leaf springs:

1. High level of precision in finished product dimensions due to the use of automatic equipments

2. More than 22 years' experience in leaf spring, there have many part sizes and load capacities for optional

3. Due to the strong technical team and R&D capabilities, OEM specifications are available

4. Wide range of models and configurations due to the product accumulation

5. Reliability in the performance under the strict product quality inspection

6. Optimization of weight under the optimized product design

7. Raw Material of excellent quality from our partner steel mill

8. Innovation in processes with exclusive technology under our experienced engineers

Applications

The main three styles of leaf springs:

1. Multi Leaf Spring – This type of leaf spring has more than 1 leaf in its assembly. It consists of a center bolt that properly aligns the leaves and clips to resist its individual leaves from twisting and shifting.

2. Mono Leaf Spring – Consists of one main leaf where the material’s width and thickness are constant. The spring rate is lighter than other styles of leaf springs and usually requires a device to control positive and negative torque loads as well as requiring coil springs to hold the chassis at ride height.

3. Parabolic Single Leaf – Consists of one main leaf with a tapered thickness. This style is sufficient to control axle torque and dampening, while maintaining ride height. The advantage of this style is that the spring is lighter than the multi-leaf.

The functions of automobile leaf spring:

1. Holding the chassis at ride height

2. Controls the rate at which the chassis rolls

3. Controls the rear end wrap up

4. Controls axle dampening

5. Controls lateral forces such as side load, pan hard, or side bite rate

6. Controls brake dampening forces

7. Sets wheel base lengths during acceleration and deceleration

Reference

Provide different types of leaf springs which include conventional multi leaf springs, parabolic leaf springs, air linkers and sprung drawbars.

In terms of vehicle types, it include heavy duty semi trailer leaf springs, truck leaf springs, light duty trailer leaf springs, buses and agricultural leaf springs.

Production

Packing & Shipping

QC equipments

Our advantage

Quality aspect:

Thickness less than 20mm. We use material SUP9

Thickness from 20-30mm. We use material 50CRVA

Thickness more than 30mm. We use material 51CRV4

Thickness more than 50mm. We choose 52CrMoV4 as the raw material

We strictly controlled the steel temperature around 800 degree.

We swing the spring in the quenching oil among 10 seconds according to the spring thickness.

Each assembling spring set under stress peening.

Fatigue test can reach over 150000 cycles.

Each item use electrophoretic paint

Salt spray testing reach 500 hours

Technical aspect

1、High-quality materials: Our factory uses specialized steel material to ensure the durability and resilience of customers’leaf springs.

2、Advanced manufacturing processes: Utilizing cutting-edge machinery and techniques allows for precision shaping and forming of the leaf springs.

3、Customization capabilities: Our factory has the ability to tailor leaf springs according to specific requirements, such as load capacity and dimensions.

4、Quality control measures: Stringent testing and inspection protocols ensure that each leaf spring meets industry standards for performance and reliability.

5、Engineering expertise: Our factory may have a team of skilled engineers who can design and optimize leaf springs for various applications.

Service aspect

1、Excellent team with rich experience

2、Think from the perspective of customers, deal with the needs of both sides systematically and professionally, and communicate in a way that customers can understand

3、7x24 working hours ensure our service systematical, professional, timely and efficient.