Welcome To CARHOME

China Manufacturer Parabolic Leaf Spring For Trailer Parts

Detail

The leaf spring is suitable for heavy duty truck

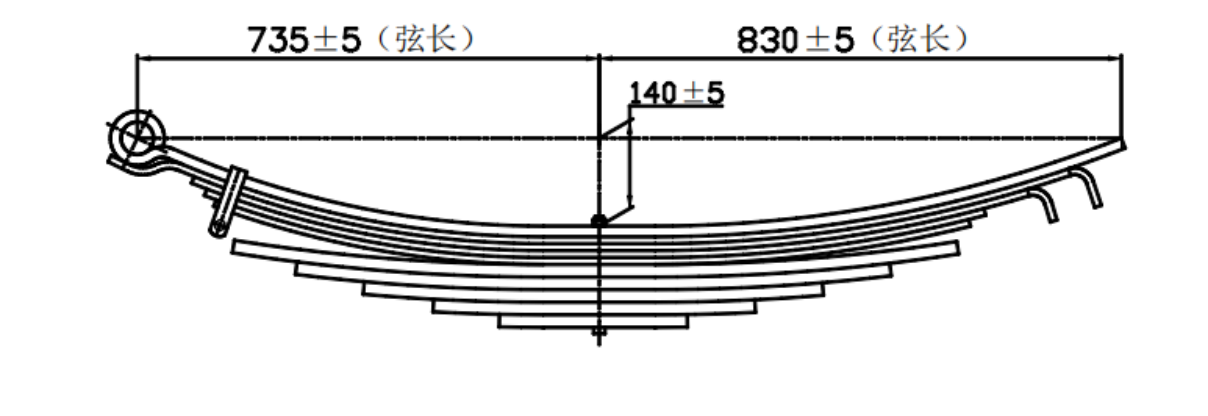

1. The item total has 10 pcs, the raw material size is 76*11/17/20

2. Raw material is SUP9

3. The free arch is 140±6mm, the development length is 1605, the centre hole is 13.5

4. The painting use electrophoretic painting

5. We also can produce base on client's drawings to design

Are leaf springs stronger than coil springs?

Leaf springs and coil springs are two different types of suspension systems commonly used on vehicles, each with their own unique features and benefits.

When comparing the strength of leaf springs and coil springs, several factors come into play to give a complete picture of their respective capabilities.

Leaf springs, also called frame springs, are made of multiple thin, curved steel strips tied together to form a unit. This design allows the leaf spring to effectively distribute weight and absorb shock, allowing it to support heavy loads.

The layered structure of leaf springs provides inherent strength and stiffness, allowing them to withstand significant weight without sagging or deforming.

Due to their strong construction, leaf springs are often favored in applications requiring high load-carrying capabilities, such as heavy-duty trucks, commercial vehicles, and off-road vehicles. Coil springs, on the other hand, are made from single or multiple coiled wires, providing a more flexible and adaptable suspension system.

While coil springs may not have the same inherent stiffness as leaf springs, they can be designed and engineered to provide excellent strength and durability for a variety of applications.

Coil springs are designed to achieve more customized suspension characteristics such as responsiveness and comfort, making them popular in passenger cars and performance-oriented applications.

In terms of direct comparison, it's important to note that the strength of leaf springs and coil springs depends on the specific requirements and intended use of the vehicle.

For heavy-duty applications where load-carrying capacity and durability are critical, leaf springs are generally considered sturdier due to their rugged construction and ability to handle large loads.

The layered structure of the leaf spring distributes the load across multiple steel strips, enhancing its overall strength and elasticity. In contrast, coil springs are known for their ability to provide precise handling, improve ride comfort, and enhance suspension articulation.

While they may not match the original load-carrying capabilities of leaf springs in heavy-duty applications, coil springs can be engineered using premium materials and advanced design techniques to provide impressive strength and reliability, especially in terms of responsiveness and Applications with high dynamic performance requirements.

In summary, the strength of leaf springs and coil springs should be evaluated based on specific vehicle requirements and usage scenarios. Leaf springs are often favored for their strong load-handling capabilities, making them sturdier in heavy-duty applications.

At the same time, coil springs offer versatility and customized performance characteristics, demonstrating strength in different aspects of suspension function.

Ultimately, the choice between leaf springs and coil springs depends on the unique needs of the vehicle and the desired balance between load-carrying capacity, handling, and comfort.

Applications

How can I make my leaf spring truck ride better?

Improving the ride quality of a leaf-sprung truck requires consideration of various factors that affect overall suspension performance.

Leaf spring suspension systems are known for their durability and load-carrying capabilities, but they can also be optimized to improve ride comfort and handling characteristics.

Here are some strategies for making your leaf spring truck drive better:

Upgrade leaf springs:

Investing in high-quality aftermarket leaf springs that are designed with ride comfort in mind can significantly improve your suspension's performance. Look for leaf springs with advanced materials and designs that provide a smoother ride without compromising load-carrying capacity. For example, progressive leaf springs can provide a more compliant ride while maintaining stability during heavy-duty use.

Shock Absorbers:

Upgrading the shock absorbers or dampers on your leaf spring truck can significantly improve ride quality. Consider choosing shock absorbers that are specifically tuned to complement the characteristics of leaf springs, providing effective damping and control on a variety of road surfaces. Adjustable shock absorbers allow you to fine-tune damping settings to suit your preferences and driving conditions.

Spring Flip Conversions:

For off-road enthusiasts, spring flip conversions are a viable option for improving ride quality and connecting the suspension on uneven terrain. This modification involves relocating the leaf springs from below the axle to above the axle, thereby increasing ground clearance and improving suspension travel. Combined with properly matched shock absorbers, this conversion can enhance the off-road performance and ride comfort of your leaf spring truck.

Suspension Bushings:

Worn or deteriorated suspension bushings can cause poor ride quality and reduce handling precision. Replacing old bushings with high-quality polyurethane or rubber bushings can help minimize unwanted vibration and noise, resulting in a more comfortable ride. Upgraded bushings also help provide better axle control and stability during cornering and braking.

Tires and Wheels:

Tire and wheel selection can have a significant impact on ride quality and overall performance. Choose tires with the right sidewall profile and tread pattern to complement the leaf spring suspension, provide good traction and absorb road imperfections. Additionally, choosing lightweight wheels can reduce unsprung weight and improve suspension responsiveness and ride comfort.

Vehicle Weight Distribution:

Pay attention to weight distribution within your truck, as unbalanced loads can affect suspension behavior and ride quality. Proper distribution of cargo and ensuring balanced weight distribution help optimize the performance of the suspension and reduce the potential for harsh ride characteristics.

Regular Maintenance:

Keeping leaf springs, shackles, and other suspension components in good condition with regular maintenance is critical to ensuring optimal ride quality. Lubricating spring bushings and ensuring proper alignment and wheel balance can help achieve a smoother, more controllable ride.

By considering these strategies and possibly implementing them in combination, you can improve the ride quality and overall performance of your leaf spring truck, thereby improving comfort and handling characteristics. It's important to evaluate your specific driving needs and preferences to determine the most effective combination of leaf spring suspension system modifications and upgrades.

Reference

Provide different types of leaf springs which include conventional multi leaf springs, parabolic leaf springs, air linkers and sprung drawbars.

In terms of vehicle types, it include heavy duty semi trailer leaf springs, truck leaf springs, light duty trailer leaf springs, buses and agricultural leaf springs.

Production

Packing & Shipping

QC equipments

Our advantage

Quality aspect:

Thickness less than 20mm. We use material SUP9

Thickness from 20-30mm. We use material 50CRVA

Thickness more than 30mm. We use material 51CRV4

Thickness more than 50mm. We choose 52CrMoV4 as the raw material

We strictly controlled the steel temperature around 800 degree.

We swing the spring in the quenching oil among 10 seconds according to the spring thickness.

Each assembling spring set under stress peening.

Fatigue test can reach over 150000 cycles.

Each item use electrophoretic paint

Salt spray testing reach 500 hours

Technical aspect

1、Consistent dimensional accuracy: A reputable leaf spring factory ensures precise manufacturing processes, resulting in leaf springs with consistent dimensions and tolerances.

2、High-strength materials: Quality leaf spring factories use high-strength materials such as SUP9, SUP10, or 60Si2Mn to ensure durability and longevity of the leaf springs.

3、Advanced heat treatment: Employing advanced heat treatment methods increases the strength and flexibility of the leaf springs, enhancing their performance under heavy loads and harsh conditions.

4、Corrosion resistance: Quality leaf spring factories implement effective anti-corrosion measures, such as galvanization or powder coating, to protect the leaf springs from rust and deterioration, extending their service life.

5、Rigorous testing procedures: Stringent quality control measures, including fatigue testing, load testing, and metallurgical analysis, ensure that each leaf spring meets performance and safety standards.

Service aspect

1、Customized solutions: The factory offers personalized consulting to provide tailored leaf spring designs based on specific customer requirements.

2、Responsive customer support: Efficient communication channels enable timely response to inquiries and technical assistance.

3、Quick turnaround times: The factory aims to provide fast order processing and delivery to meet urgent customer needs.

4、Product expertise: The factory's team can offer guidance on selecting the right type and configuration of leaf springs for different applications.

5、Warranty and after-sales service: Comprehensive warranties and support services provide peace of mind to customers after purchasing leaf springs.