Welcome To CARHOME

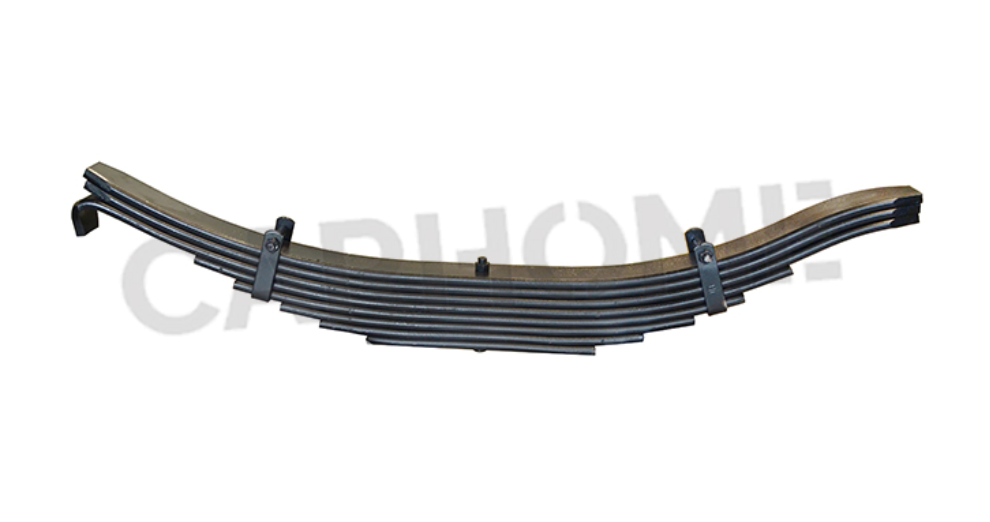

Leaf Spring For FRUEHAUF Semi-Trailer

Detail

The leaf spring is suitable for north American market semi-trailer

1. The item total has 8 pcs, the raw material size is 76*13 for first to sixth leaf, the seventh and eighth leaf is 76*12

2. Raw material is SUP9

3. The free arch is 92±5mm, the development length is 1102, the centre hole is 12.5mm

4. The painting use electrophoretic painting

5. We also can produce base on client's drawings to design

TRA series leaf springs OEM numbers:

| OEM No. | CAPACITY(LB) | LENGTH(INCH) | ASSY | BRAND |

| TRA2752 | 22,400 LB | 21.25-22.25 | 2L | HUTCH |

| TRA2754 | 22,400 LB | 21.25-22.50 | 2L | HUTCH |

| TRA2726 | 22,400 LB | 21.25-22.50 | 3L | HUTCH |

| TRA2727 | 22,400 LB | 21.25-22.55 | 3L | HUTCH |

| TRA2728 | 22,400 LB | 21.25-22.56 | 3L | HUTCH |

| TRA2740 | 24,000 LB | 21.25-22.48 | 3L | HUTCH |

| TRA2741 | 24,000 LB | 21.25-22.55 | 3L | HUTCH |

| TRA693 | 10,000 LB | 21.50-21.50 | 3L | UCD |

| TRA697 | 10,000 LB | 21.31-21.31 | 3L | FRUEHAUF |

| TRA699 | 14,000 LB | 21.69-21.69 | 4L | FRUEHAUF |

| TRA2732 | 11,000 LB | 21.55-21.88 | 8L | HUTCH |

| TRA2297 | 14,000 LB | 21.125-20.63 | 9L | HUTCH |

| TRA2270 | 11,000 LB | 21.69-21.69 | 8L | HUTCH |

| TRA2260 | 11,000 LB | 20.38-21.88 | 8L | HUTCH |

Applications

How do I know what leaf springs I need for my trailer?

To determine which leaf springs are right for your trailer, you need to consider several factors.

First, you should determine the required weight of your trailer. This can be calculated by adding the weight of the trailer when fully loaded to the weight of the cargo it is carrying.

Once you have this number, you can choose a leaf spring rated to support that weight.

Next, you should consider the type of suspension system your trailer currently has, as well as the size of the existing leaf springs.

This will help you ensure that the new leaf springs are compatible with your trailer’s suspension system and are installed correctly.

It’s also important to consider the trailer’s intended use. If you frequently transport heavy items or drive over rough terrain, you may want to invest in heavy-duty leaf springs to provide greater durability and support.

Additionally, you may want to consult a professional or refer to the trailer manufacturer’s guidelines to ensure you select the correct leaf springs for your specific trailer model.

Ultimately, the key to determining the right leaf spring for your trailer is understanding the trailer’s weight capacity, suspension system, dimensions, and intended use.

By carefully considering these factors, you can confidently choose the right leaf spring to meet the needs of your trailer.

Reference

Provide different types of leaf springs which include conventional multi leaf springs, parabolic leaf springs, air linkers and sprung drawbars.

In terms of vehicle types, it include heavy duty semi trailer leaf springs, truck leaf springs, light duty trailer leaf springs, buses and agricultural leaf springs.

Production

Packing & Shipping

QC equipments

Our advantage

Quality aspect:

Thickness less than 20mm. We use material SUP9

Thickness from 20-30mm. We use material 50CRVA

Thickness more than 30mm. We use material 51CRV4

Thickness more than 50mm. We choose 52CrMoV4 as the raw material

We strictly controlled the steel temperature around 800 degree.

We swing the spring in the quenching oil among 10 seconds according to the spring thickness.

Each assembling spring set under stress peening.

Fatigue test can reach over 150000 cycles.

Each item use electrophoretic paint

Salt spray testing reach 500 hours

Technical aspect

1、Consistent Performance: Leaf springs have consistent performance characteristics, helping vehicle occupants achieve predictable handling and ride quality.

2、Weight distribution: Leaf springs effectively distribute the weight of the vehicle and its cargo, helping to balance load distribution and improve stability.

3、Impact resistance: Leaf springs can absorb and buffer the impact of uneven road surfaces, making the ride smoother and more comfortable.

4、Corrosion resistance: Properly treated and coated leaf springs show good corrosion resistance, improving their service life and reliability in various environments.

5、Environmental benefits: Leaf springs can be recycled and reused, providing environmental benefits in terms of sustainability and resource conservation.

Service aspect

1、Compatibility with accessories: Leaf springs can be designed to accommodate a variety of suspension accessories and modifications, enhancing their adaptability to different vehicle setups.

2、Noise Reduction: Well-designed leaf springs help reduce noise and vibration levels, improving overall vehicle occupant comfort.

3、Enhanced traction: Leaf springs help improve traction and stability, especially in off-road and heavy-duty applications.

4、Regulatory compliance: Leaf spring factories can ensure that their products comply with relevant industry standards and regulations, providing assurance for quality and safety.

5、Industry expertise: Established leaf spring factories usually have extensive industry expertise and experience and can provide customers with valuable insights and support for optimizing suspension system performance.

![[Copy] TVarious Types Leaf Springs for Truck Parts](https://cdn.globalso.com/chleafspring/117.jpg)