Welcome To CARHOME

Z Type Air Linker Air Suspension for Heavy Duty Semi Trailer

Detail

This item is suitable for BPW Air Suspension Semi-Trailer

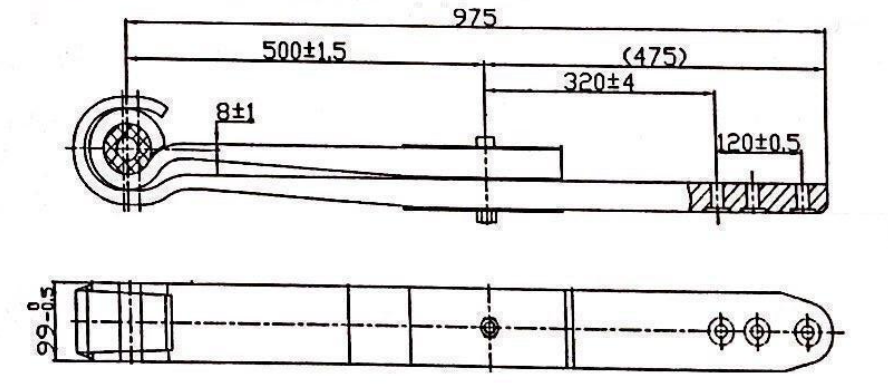

1. The oem number is LTGAK11-030500, the specification is 100*38, the raw material is 51CrV4

2. The item total has two pcs, first pcs with eye ,use rubber bush (φ30×φ68×100), the length from the centrl of the eye to the centrl hole is 500mm. The second pcs is Z type, the length from the cover to the end is 975mm

3. The height of the spring is 150mm

4. The painting use electrophoretic painting, the color is drak grey

5. It use with air kit together is the air suspension

6. We also can produce base on client's drawings design

Air Linkers Part Numbers:

| Item Number | Type | Specification(mm) | Length(mm) |

| 508204260 | BPW | 100*22 | 1170 |

| 880305 | BPW | 100*27 | 1172 |

| 880301 | BPW | 100*19 | 1170 |

| 880300 | BPW | 100*19 | 1173 |

| 880312 | BPW | 100*18 | 930 |

| 880323 | BPW | 100*19 | 970 |

| 508213190/881360 | BPW | 100*50 | 940 |

| 881508 | BPW | 100*48 | 870 |

| 508212640/881386 | BPW | 100*38 | 975 |

| 880305 | BPW | 100*27 | 1220 |

| 880301 | BPW | 100*19 | 1220 |

| 880355 | BPW | 100*38 | 940 |

| 901590 | SCANIA | 100*45 | 950 |

| 1421061/901870 | SCANIA | 100*45 | 1121 |

| 1421060/901890 | SCANIA | 100*45 | 1121 |

| 508213240 | BPW | 100*43 | 1015 |

| 508213260 | BPW | 100*38 | 920 |

| 508212830 | BPW | 100*43 | 1020 |

| 508213560/881513 | BPW | 100*48 | 940 |

| 508213240/881366 | BPW | 100*43 | 1055 |

| 508213260/881367 | BPW | 100*38 | 930 |

| 508212670 | BPW | 100*38 | 945 |

| 508213360/881381 | BPW | 100*43 | 940 |

| 508213190 | BPW | 100*50 | 940 |

| 881342 | BPW | 100*48 | 940 |

| 508213670/881513 | BPW | 100*50 | 940 |

| 21222247/887701/ F260Z104ZA75 | BPW | 100*48 | 990 |

| F263Z033ZA30 | BPW | 100*40 | 633 |

| 886162 | BPW | 100*48 | 900 |

| 886150/3149003602 | BPW | 100*38 | 895 |

| 887706 | BPW | 100*35 | 990 |

Applications

The Air Linker is mainly applicable to the automobile air suspension.

● It is usually composed of one or two spring leaves, which are used symmetrically with left and right.

● It is installed between the axle and the air suspension bracket.

● It is formed as a whole, and its structure includes a straight part, a bending part and a eye rolling part.

● The rolled eye is equipped with a rubber composite bushing.

● The common material specifications of the guide arm are from 90 to 100 mm in width and from 20 to 50 mm in thickness.

The difference between the leaf spring and the air suspension:

● The suspension that supports the truck is a very important part that significantly affects the characteristics of the truck, so the type and condition of the suspension are important points to check when buying a used truck.

● Leaf spring is a type of suspension composed of spring plates with different lengths which is assembled near front/rear wheels of vehicles to be able to carry heavy objects.

● However, trucks which are produced lately is mainly installed a different type of spring called air suspension because it is uncomfortable to drive trucks with leaf spring.

● But leaf springs are still used on heavy commercial vehicles such as vans and trucks due to its durability.

● Leaf spring consists of multilayered spring plates. The longest spring called main spring is attached to chassis supported by shackles.

● Leaf spring makes it possible to absorb impact and vibration from a wheel by bending the spring plate. There are two types of name for the leaf spring.

● One of them is called ‘over slung’ when the leaf spring is putted on the upper side of the axle. The other one is called ‘under slung’ when the leaf spring is putted under the axle.

● The place to be putted the leaf spring depends on the vehicle type.

Advantages and disadvantages of leaf spring:

ADVANTAGES

● It can bear heavy loads

● Not expensive to repair comparatively

The material of leaf spring is made of steel so that means it is very strong and withstand heavy load. Also, it is cheaper to maintenance than the other suspension as the structure is simple.

DISADVANTAGES

● Not comfortable to ride

● It can be damaged easily

It is not comfortable to ride in, and it could jump you up when you hit a step because leaf spring is made of steel.

However, the cost to repair will be much cheaper than air suspension, so leaf springs are still used on heavy commercial vehicles such as vans and trucks.

Reference

Provide different types of leaf springs which include conventional multi leaf springs, parabolic leaf springs, air linkers and sprung drawbars.

In terms of vehicle types, it include heavy duty semi trailer leaf springs, truck leaf springs, light duty trailer leaf springs, buses and agricultural leaf springs.

Production

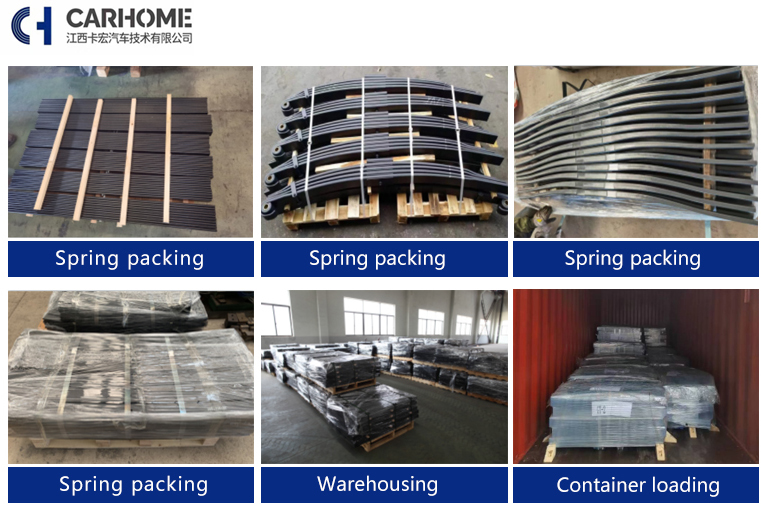

Packing & Shipping

QC equipments

Our advantage

Thickness less than 20mm. We use material SUP9

Thickness from 20-30mm. We use material 50CRVA

Thickness more than 30mm. We use material 51CRV4

Thickness more than 50mm. We choose 52CrMoV4 as the raw material

We strictly controlled the steel temperature around 800 degree.

We swing the spring in the quenching oil among 10 seconds according to the spring thickness.

Each assembling spring set under stress peening.

Fatigue test can reach over 150000 cycles.

Each item use electrophoretic paint

Salt spray testing reach 500 hours

Technical aspect

1、QC management system:Implementing IATF 16949-2016;

2、Services quality management system: Implementing ISO 9001-2015

3、Product quality standards: GB/T 19844-2018, GT/T 1222-2007

4、Raw material from the top 3 steel mills in China

5、Finished products tested by Stiffness Testing Machine, Arc Height Sorting Machine; and Fatigue Testing Machine

6、Processes inspected by Metallographic Microscope, Spectrophotometer, Carbon Furnace, Carbon and Sulfur Combined Analyzer

7、Application of automatic CNC equipment such as Heat Treatment Furnace and Quenching Lines, Tapering Machines, Cutting Machine and Robot-assitant production

8、Optimize product mix and reduce customer purchasing cost

9、Provide design support,to design leaf spring according to customer cost

Service aspect

1、More than 10 spring engineers' support,excellent team with rich experience

2、Think from the perspective of customers, deal with the needs of both sides systematically and professionally, and communicate in a way that customers can understand

3、7x24 working hours ensure our service systematical, professional, timely and efficient