Welcome To CARHOME

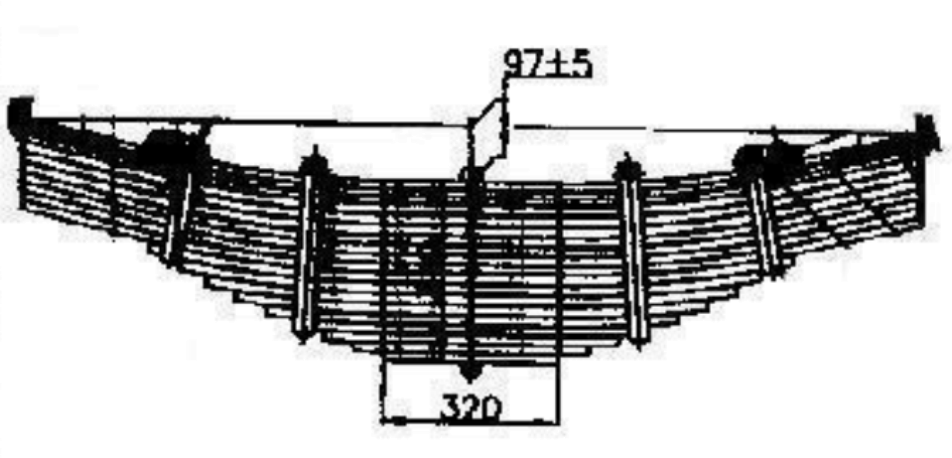

BPW Bogie Suspension HJ AXLE Leaf Spring

Detail

The Bogie leaf spring is suitable for special and heavy weight semi-trailer, it install with BPW, FUWA, HJ, L1 Axle

1. The capacity: 24,000 to 32,000 kgs

2. The item total has 19 pcs, the raw material size is 90*14 for first、second and third leafs, the fourth、fifth、eleventh to fourteenth is 90*18, others are 90*16

3. Raw material is SUP9

4. The free arch is 96±5mm, the development length is 1036, the centre hole is 18.5

5. The painting use electrophoretic painting

6. We also can produce base on client's drawings to design

What is bogie suspension in trucks?

Truck bogie suspension refers to a suspension system commonly used in heavy vehicles such as trucks and trailers.

It consists of a set of two or more axles connected to the frame or chassis through a system of springs, shock absorbers and linkages.

The main purpose of bogie suspension is to evenly distribute the weight of the vehicle and its cargo over multiple axles, thereby reducing the effects of road irregularities and providing a smoother ride.

A bogie suspension system is particularly beneficial for trucks that need to carry heavy loads over long distances because it helps improve stability, traction, and overall handling.

By spreading weight across multiple axles, bogie suspension also helps minimize wear and tear on individual components, thereby reducing maintenance costs and extending the life of the vehicle.

Additionally, bogie suspension is designed to adapt to different types of terrain and road conditions, making it a versatile option for trucks that need to operate in different environments.

This type of suspension system comes in a variety of configurations, including leaf spring, air suspension and coil spring setups, each offering unique advantages in terms of load capacity, ride comfort and adjustability.

Overall, bogie suspension plays a vital role in improving the performance and durability of trucks, making it an important feature for commercial vehicles that need to transport heavy loads safely and efficiently.

Applications

Bogie suspension is to reduce the common leaf spring suspension's front and rear brackets into a single bracket connected to the chassis body.

Its stress points are shared on the front and rear axles. Compared with ordinary leaf spring suspensions, bogie suspensions can carry more capacity.

This kind of Bogie suspension is less used in ordinary semi-trailers, and is mainly used in heavy semi trailer and truck.

The bogie leaf spring is use for bogie suspension, there are three types of leaf spring design:

1. 12T leaf spring (section:90×13, 90×16, 90×18, 18 leaves) for 24T bogie;

2. 14T leaf spring (section: 120×14, 120×16, 19 leaves) for 28T bogie;

3. 16T leaf spring (section: 120×14, 120×18, 120×20, 17 leaves) for 32T bogie.

What is the difference between axle and bogie?

Axles and bogies are both components of a vehicle's suspension and drivetrain, but they serve different purposes and have different characteristics.

The axle is the central shaft that rotates with the wheels and is responsible for transmitting the engine's power to the wheels.

In most vehicles, the axle is a single straight shaft that connects the wheels on either side of the vehicle. It plays a vital role in supporting the weight of the vehicle and its cargo, as well as providing the torque needed to propel the vehicle forward or reverse.

Axles are found in both front-wheel drive and rear-wheel drive vehicles, and they are often equipped with differential gears to allow the wheels to spin at different speeds when cornering.

A bogie, on the other hand, refers to a set of two or more axles connected to the frame or chassis through a system of springs, shock absorbers, and linkages.

Unlike a single axle, bogies are designed to distribute the weight of a vehicle and its load over multiple axles, thereby increasing stability, load-carrying capacity and overall performance.

Bogies are typically used in heavy-duty vehicles such as trucks, trailers and rolling stock, where the ability to carry heavy loads over long distances is critical.

One of the main differences between axles and bogies is their respective roles in supporting and distributing weight.

While axles are primarily used to transmit power and support the weight of a single wheel or pair of wheels, bogies are designed to distribute the weight of a vehicle and its cargo over multiple axles, reducing the impact of road irregularities and providing a better ride Smoother.

In addition, bogies are often equipped with additional components such as suspension systems and connecting rods to further enhance their load-bearing capacity and overall performance.

In summary, the main difference between axles and bogies is their design and functionality.

An axle is a single shaft that transmits power to the wheels, while a bogie is a set of multiple axles that work together to distribute weight and improve the performance of a heavy vehicle.

These two components are critical to the proper functioning of the vehicle's suspension and drivetrain, but they serve different purposes and are designed to meet different operating requirements.

Reference

Provide different types of leaf springs which include conventional multi leaf springs, parabolic leaf springs, air linkers and sprung drawbars.

In terms of vehicle types, it include heavy duty semi trailer leaf springs, truck leaf springs, light duty trailer leaf springs, buses and agricultural leaf springs.

Production

Packing & Shipping

QC equipments

Our advantage

Quality aspect:

Thickness less than 20mm. We use material SUP9

Thickness from 20-30mm. We use material 50CRVA

Thickness more than 30mm. We use material 51CRV4

Thickness more than 50mm. We choose 52CrMoV4 as the raw material

We strictly controlled the steel temperature around 800 degree.

We swing the spring in the quenching oil among 10 seconds according to the spring thickness.

Each assembling spring set under stress peening.

Fatigue test can reach over 150000 cycles.

Each item use electrophoretic paint

Salt spray testing reach 500 hours

Technical aspect

1、Cost-effectiveness: Due to the relatively simple design and production process of leaf springs, our factory can provide a cost-effective solution for manufacturing suspension components.

2、Durability: Leaf springs are known for their durability and ability to withstand heavy loads and harsh road conditions, making them a reliable choice for a variety of vehicles.

3、Versatility: Leaf springs are designed and manufactured to fit different vehicle types, including trucks, trailers and off-road vehicles, providing versatility for a wide range of applications.

4、Load carrying capacity: Leaf springs are capable of supporting heavy loads, our factory can make them suitable for commercial vehicles and industrial equipment that require a strong suspension system.

5、Easy to maintain: Leaf spring suspension systems are relatively easy to maintain and repair, reducing downtime and maintenance costs for vehicle owners and operators.

Service aspect

1、Stability: Leaf springs provide excellent stability and control, especially in heavy-duty vehicles, our factory can help to achieve safer and more predictable handling characteristics.

2、Long service life: If designed and manufactured properly, leaf springs can provide a long service life, thus our factory can provide greater durability and reliability to the vehicle.

3、Customization: Our factory can customize the design and specifications of leaf springs to meet the specific requirements of different vehicle manufacturers and applications.

4、Resistant to sag: Compared to other types of suspension systems, leaf springs are less prone to sag over time, our factory can maintain their load-carrying capacity and performance.

5、Off-road capability: Leaf springs are ideal for off-road vehicles, our factory providing the necessary articulation and support for traversing uneven terrain and obstacles.