Production Process Guidance of Leaf Springs

-Tapering (long tapering and short tapering)(Part 3)

1. Definition:

Tapering/Rolling process: Using a rolling machine to taper spring flat bars of equal thickness into the bars of different thickness.

Generally, there are two tapering processes: long tapering process and short tapering process. When the tapering length is more than 300mm, it is called long tapering.

2. Application:

All spring leaves.

3.1. Inspection before tapering

Before rolling, check the inspection mark of punching (drilling) center hole of spring flat bars in the previous process, which must be qualified; at the same time, verify whether the specification of spring flat bars meets the rolling process requirements, and the rolling process can be started only when it meets the process requirements.

3.2. Commissioning a rolling machine

According to the rolling process requirements, choose the straight-line or parabolic rolling method. The trial rolling shall be carried out with the end positioning. After the trial rolling passes the self inspection, it shall be submitted to the inspector for review and approval, and then the formal rolling can be started. Generally, from the beginning of tapering to the rolling of 20 pieces, it is necessary to be diligent in inspection. When rolling 3-5 pieces, it is necessary to check the rolling size once and adjust the rolling machine once. Random inspection can be carried out according to a certain frequency only after the rolling length, width and thickness are stable and qualified.

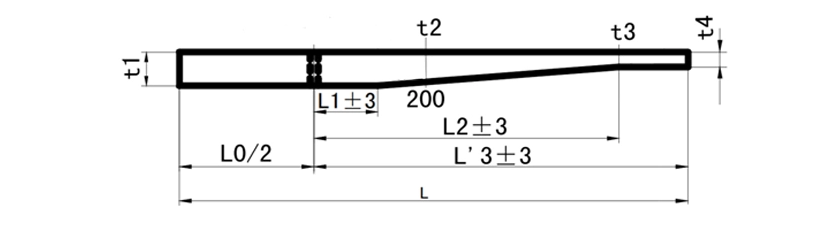

As shown in Figure 1 below, the parameters setting of leaf spring rolling.

(Figure 1. Rolling parameters of a leaf spring)

3.3.1. Explanations of rolling thickness

Rolling thickness t1 ≥24mm, heating with a medium frequency furnace.

Rolling thickness t1<24mm, the end heating furnace can be selected for heating.

3. Explanations of material for rolling

If the material is 60Si2Mn, the heating temperature is controlled at 950-1000 ℃.

If the material is Sup9, the heating temperature is controlled at 900-950 ℃.

3.4. Rolling and cutting ends

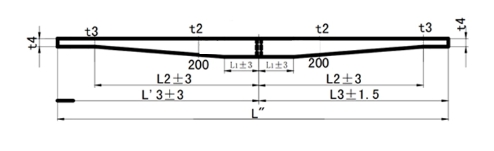

As shown in Figure 2 below. Position the left end of the flat bar and roll the heated right side of the bar according to the requirements. After the tapering meets the size requirements, cut the right end according to the design size. Similarly, the rolling and end cutting on the left the flat bar shall be carried out. Long rolled products need to be straightened after rolling.

(Figure 2. Tapering parameters of a leaf spring)

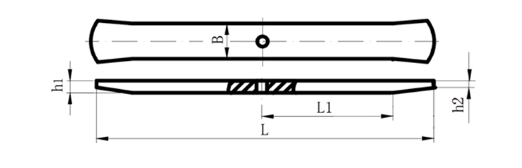

In case of short tapering, if the end trimming is required, and the ends shall be trimmed according to the above method. If the end trimming is not required, the ends of the leaf spring look like a fan. As shown in Figure 3 below.

(Figure 3. Short tapering parameters of a leaf spring)

3.5. Material Management

The final rolled qualified products shall be stacked on the material rack with a flat-straight surface downward, and the inspection qualification mark for three sizes (length, width and thickness) shall be made, and the work transfer card shall be pasted.

It is forbidden to throw products around, causing surface damage.

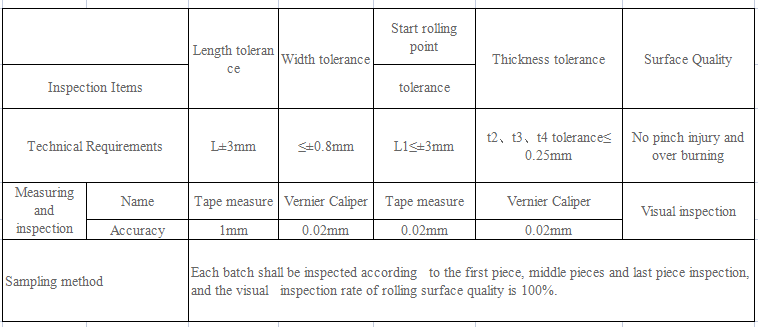

4. Inspection standards (Refer to the standard: GBT 19844-2018 / ISO 18137: 2015 MOD Leaf Spring – Technical Specifications)

Measure the finished products according to figure 1 and Figure 2. The inspection standards of rolled products are shown in Table 1 below.

Post time: Mar-27-2024