Welcome To CARHOME

Light Duty Truck and Trailer Parts Suspension OEM Custom Leaf Spring

Detail

The leaf spring is suitable for light duty truck

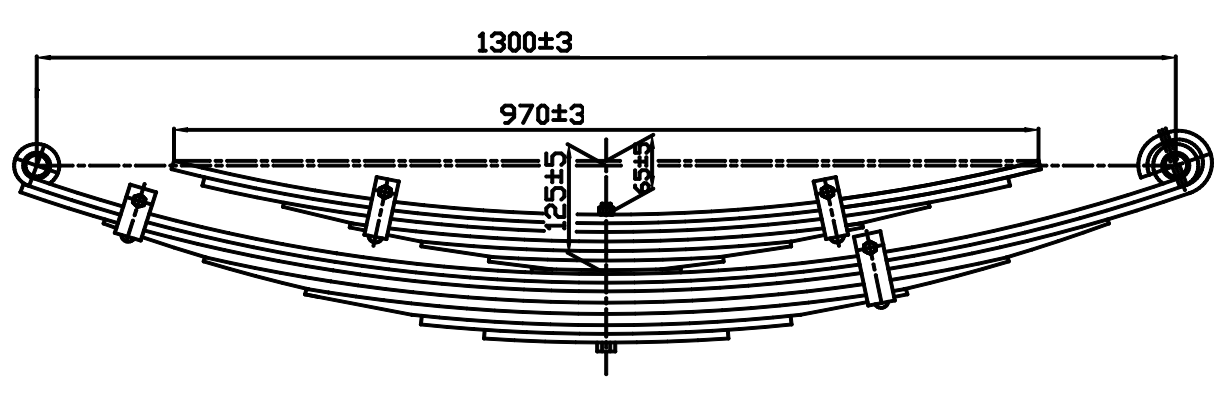

1. The item total has 14 pcs, the raw material size is 70*10 for the first and second leaf, from the third to sixth leaf is 70*11, the tenth、eleventh and twelfth is 70*13

2. Raw material is SUP9

3. The main free arch is 125±5mm, the helper free arch is 65mm±5, the development length is 1300, the centre hole is 12.5

4. The painting use electrophoretic painting

5. We also can produce base on client's drawings to design

Hot selling leaf springs OEM numbers:

| S/N | OEM No. | S/N | OEM No. | S/N | OEM No. |

| 1 | 911B-0508-R2 | 21 | 48210-5180B-R2 | 41 | SH63-1430-FA-HD |

| 2 | 911B-1102A-F1 | 22 | 269087-R2 | 42 | 227-M-FA-0 |

| 3 | 48220-5891A-R1 | 23 | 470131-R1 | 43 | 3W920-FA-3L |

| 4 | 352-320-1302-F1 | 24 | 470131-R2 | 44 | 3V790-RA+HA 3L |

| 5 | FCP37-R1 | 25 | 09475-01-T1 | 45 | 48120-5380B-M20 FA |

| 6 | FCP37A-R1 | 26 | EZ9K869691101-F1 | 46 | W023-34-010B-FA |

| 7 | 48210-60742 | 27 | EZ9K869691101-F2 | 47 | 8-94118-505-1-RA |

| 8 | 48210-8891A-R1 | 28 | EZ9K869691102-F1 | 48 | 8-94101-345-0-FA |

| 9 | 70×11×1300 M12.5 | 29 | EZ9K869691102-F2 | 49 | 54010-1T700-FA |

| 10 | 60×7×1300 M10.5 | 30 | EZ9K869691102-F3 | 50 | 265627-FA |

| 11 | HOWO90161800 | 31 | SCN-1421061-RH | 51 | W782-28-010-RA |

| 12 | 833150P-R1 | 32 | SCN-1303972 | 52 | W782-34-010-FA |

| 13 | 833150P-R2 | 33 | SCN-1421060-LH | 53 | 8-97092-450-M-FA |

| 14 | 833150P-R3 | 34 | XCMG 9020-1780-F1 | 54 | 535173-RA |

| 15 | 55020-Z5176-H1 | 35 | XCMG 9020-1780-F2 | 55 | 1-51300-524-0-RA |

| 16 | 48110-5350A-F2 | 36 | XCMG 9020-1780-F3 | 56 | 1-51130-433-0-FA |

| 17 | 48110-5350A-F1 | 37 | MK383732-FA | 57 | 1-51300-524-0-HA |

| 18 | 48210-2002B-R1 | 38 | 3V610-HA 5L | 58 | MB339052-RA |

| 19 | 48210-5180B-R | 39 | MC114890 RA | 59 | MR448147A-RA |

| 20 | 48220-3430A-R2 | 40 | CW53-02Z61-FA | 60 | MC110354-FA |

Applications

Truck Leaf Springs And Hauling: What You Need To Know

In a truck, the leaf springs are the main component keeping the wheels moving smoothly over bumps and potholes without transferring the jarring to the body of the truck. This makes your ride smoother and easier on your passengers, as well as on any type of load that you may be carrying.

Without leaf springs and the rest of your vehicle suspension, your drive would be extremely uncomfortable. However, not everyone realizes that leaf springs come in many different load capacities for the same type of truck. If you're going to use your truck to haul heavy loads, then you need to know what weight your leaf springs can hold so that you don't exceed the limit they can carry. Options are available to improve the carrying capacity of the leaf springs and suspension, but knowing how large your biggest load will be is an important first step.

For light duty trailer leaf springs, There are 6 end treatment styles:

1. Double eyes slipper springs (Capacity 300-4000lbs),

2. Open eye slipper springs (Capacity 1500-2750lbs),

3. Flat end slipper springs (Capacity 300-3000lbs),

4. Radius end slipper springs (Capacity 230-7500lbs),

5. Hook end slipper springs (Capacity 750-4000lbs),

6. Parabolic type springs.

These leaf spring are very popular in North America, Australia and New Zealand markets.

Reference

Provide different types of leaf springs which include conventional multi leaf springs, parabolic leaf springs, air linkers and sprung drawbars.

In terms of vehicle types, it include heavy duty semi trailer leaf springs, truck leaf springs, light duty trailer leaf springs, buses and agricultural leaf springs.

Production

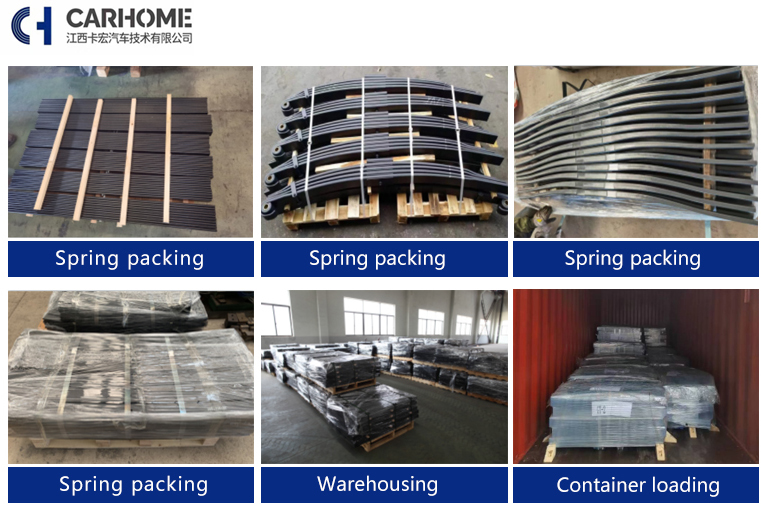

Packing & Shipping

QC equipments

Our advantage

Thickness less than 20mm. We use material SUP9

Thickness from 20-30mm. We use material 50CRVA

Thickness more than 30mm. We use material 51CRV4

Thickness more than 50mm. We choose 52CrMoV4 as the raw material

We strictly controlled the steel temperature around 800 degree.

We swing the spring in the quenching oil among 10 seconds according to the spring thickness.

Each assembling spring set under stress peening.

Fatigue test can reach over 150000 cycles.

Each item use electrophoretic paint

Salt spray testing reach 500 hours

Technical aspect

1、Product technical standards:implementation of IATF16949

2、More than 10 spring engineers' support

3、Raw material from the top 3 steel mills

4、Finished products tested by Stiffness Testing Machine, Arc Height Sorting Machine; and Fatigue Testing Machine

5、Processes inspected by Metallographic Microscope, Spectrophotometer, Carbon Furnace, Carbon and Sulfur Combined Analyzer; and Hardness Tester

6、Application of automatic CNC equipment such as Heat Treatment Furnace and Quenching Lines, Tapering Machines, Blanking Cutting Machine; and Robot-assitant production

7、Optimize product mix and reduce customer purchasing cost

8、Provide design support,to design leaf spring according to customer cost

Service aspect

1、Excellent team with rich experience

2、Think from the perspective of customers, deal with the needs of both sides systematically and professionally, and communicate in a way that customers can understand

3、7x24 working hours ensure our service systematical, professional, timely and efficient.